Hydro-Mechanical Simulations

The presence of groundwater has an impact on productivity at underground operations. Conventional design approaches focus on either hydrological or mechanical simulations, without acknowledging the interconnectivity of both problems.

To overcome this limitation Beck Engineering developed a framework to efficiently solve hydro-mechanically coupled problems even for large-scale, three dimensional, discontinuum models with complex geometry and multiple excavation sequences.

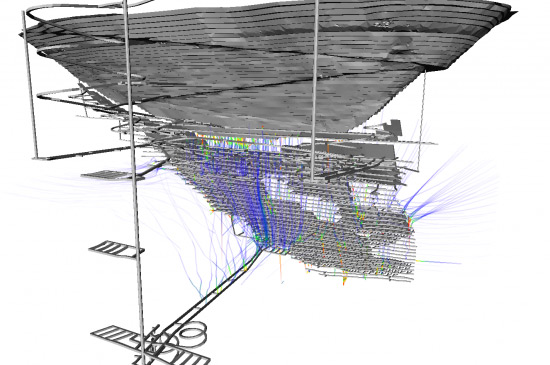

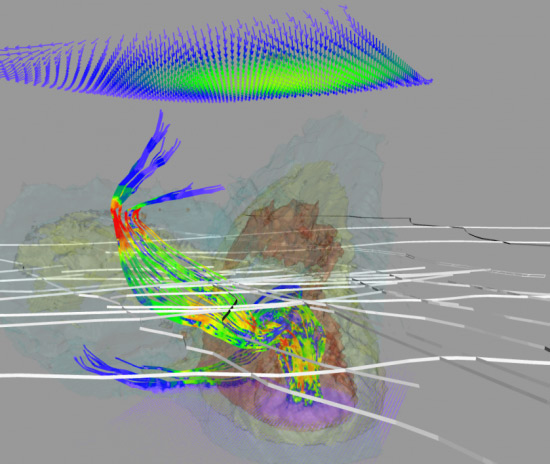

Our simulations capture the increase in hydraulic conductivity due to the evolution of rock mass damage. They also accurately predict the developing flow paths along discontinuities.

Beck Engineering has been developing coupled hydro-mechanical models since 2007 for some of the world’s largest open pit and underground operations.

Speak to one of our engineers to learn more about our simulation techniques and capabilities.

Flow-traces in a mine-scale coupled hydro-mechnical discontinuous finite element model

Our Simulations

- Complex geometry and mining sequence:

Accurate simulation of rock behaviour for each geotechnical domain, as well as explicitly built discontinuities allowing realistic slip, separation and damage. - Hydraulic properties of each domain can be

- isotropic, orthotropic, fully anisotropic,

- rock mass damage dependent:

nonlinear increase in permeability with increase in rock mass damage

- Flow along and across discontinuities at different scales.

- Transient or steady-state analyses.

- Solution dependent boundary conditions.

WHAT YOU GET

- Over 15 years of experience in building and running sophisticated geotechnical models for the mining industry

- An international team of mining and rock mechanics engineers with more than 100 years of combined professional experience

- High resolution models with high similitude forecasting of rock mass performance

- Results are presented in a form that is unambiguous and which can be more easily understood

- A simulation framework designed to your specifications and not limited due to implementation constraints

- Full three-dimensional results database available for site engineers to use for ongoing confirmation, analysis and refinement.

- Full transparency: We will assist you how to get the most out of the results, what information would improve the forecasts and work with you to continually improve your mine.

Very significant damage, as well as a high flow system evolves at the confluence of major fault structures due to fluid influx through the magma chamber at the bottom of the image.

back

back