Ground Support

At BECK Engineering we understand the importance of a well designed ground support system for a safe and cost-effective work environment. Conventional analysis often focuses on individual ground support elements rather than a combined ground support system. To reliably simulate the ground support response, ground deformation must be captured accurately on the correct length scale.

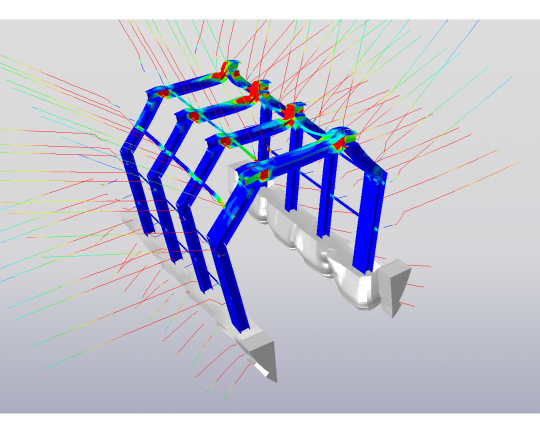

Beck Engineering uses multi-scale multi-physics simulations as these are the most efficient approach for assessing a ground support system’s capacity and demand over a range of different environments. This approach also enables the ground support system to be tested to failure, improving the understanding of the maximum capacity of the system. The Simulation Aided Engineering workflow allows clients to efficiently test different designs and sequences over a range of conditions. The result is a more accurate quantification of geotechnical performance.

Beck Engineering have been world leaders in physics based rock mechanics simulations for over 15 years. We have applied this methodology of ground support systems including rock bolts and cable bolts, mesh reinforced shotcrete, precast concrete liners and steel sets. This approach has been applied in excavations ranging from individual tunnels to complex excavations such as block cave extraction levels and crusher chambers.

Speak to one of our engineers about improving your understanding of the performance of your ground support system.

Our approach

BE uses a multi-scale, discontinuum approach to improve the simulation reliability of ground support capacity and demand. We design support systems for any application, and specialise in:

- High deformation and seismic loading environments.

- Simulating realistic mining induced seismic sources, to evaluate the sufficiency of ground support standards for seismically active mines.

- Static and dynamic validation of support standards. We simulate your support design in your ground conditions, using your mines expected mechanisms of loading and damage.

- Virtual testing of any ground support system to destruction to validate static or dynamic capacity.

- Beck Engineering’s own rock mechanics specific numerical code generates large scale, 3D Finite Element models.

- Our simulations use non-linear, strain softening, dilatant material models for each geotechnical domain.

- Faults are built explicitly to match the geotechnical structural interpretation. Slip, separation and accumulation of damage is realistically represented along faults.

- Ground support elements are represented individually in the simulation

- The full extraction history and planned mining sequence is built into the model.

- Beck Engineering’s simulations can be coupled multi-physics models. For example, hydrogeological models or particle flow codes (for simulating cave propagation)

What you get

- Powerful, non-biased, physics based predictive tool for:

- Geotechnical Engineers

- Mining Engineers

- Geologists

- Managers

- Full 3D results database available for site engineers to use for ongoing confirmation, analysis and refinement of mine design.

- Full transparency: We will assist you how to get the most out of the results, what information would improve the forecasts and work with you to continually improve your mine.

- Quick turnaround time between iterations.

A yielding system for extreme deformation. Yielding surface support beams are installed in the fibrecrete. The combination of the yielding surface support with yielding arches accommodates 750mm of wall to wall closure.

back

back