These SAE services are an addition to our traditional mining engineering services. We’ve developed the new service to answer our clients requirement for access to models of our specification, without the need to purchase licenses or retain the necessary hardware and expertise. Because our expert applied mechanics engineers build the models to your specifications, then send you the results in 4d, you get the model you require, faster and cheaper, without losing the hands-on benefits of building the model yourself. You also gain access to our QC and technical experience building multi-physics high similitude models.

What is SAE?

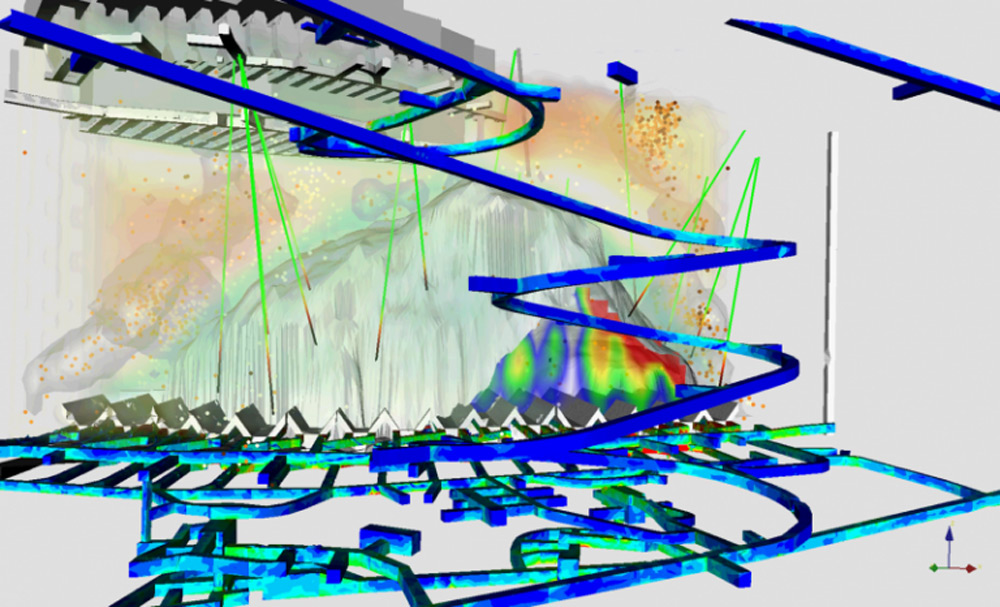

Simulation Aided Engineering is a concept for leveraging computer-based design tools to improve the engineering and design work flow. For complex mines, SAE provides a virtual laboratory for testing the bottom-line performance of various courses of action at every stage in the design process, using the best available information at the time, constrained by the physics. It should also ensure that fatally flawed designs do not advance to the next design iteration.

Its purpose is to ensure:

- that physical and economic constraints are properly appreciated at every stage from planning to operations, while

- considering uncertainty and

- promoting rapid progress towards an optimal outcome.

In concept, SAE, using high similitude, physics-based predictive tools differs little from best-practice non-SAE workflows that would have always used the best available information and tools to constrain the design. SAE is simply an update to account for the rapidity with which computations can now take place and the complexity that can now be captured with very high similitude. If integrated to its fullest extent, SAE for mining should result in more reliable mines and better trained personnel.

For more details contact Dr David Beck at +61 412 135 782 or dbeck@beckengineering.com.au.